80% plastic rotation seat

toddler seat development

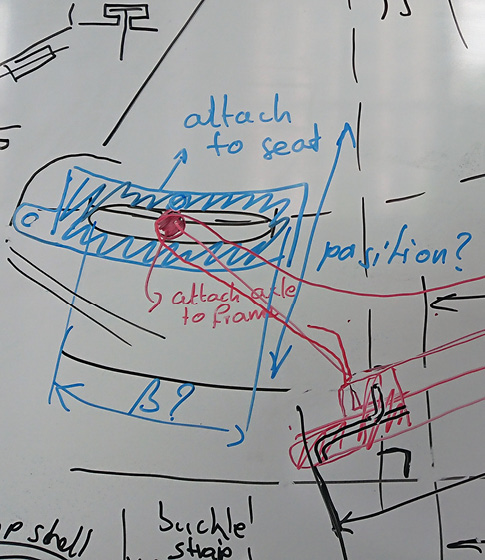

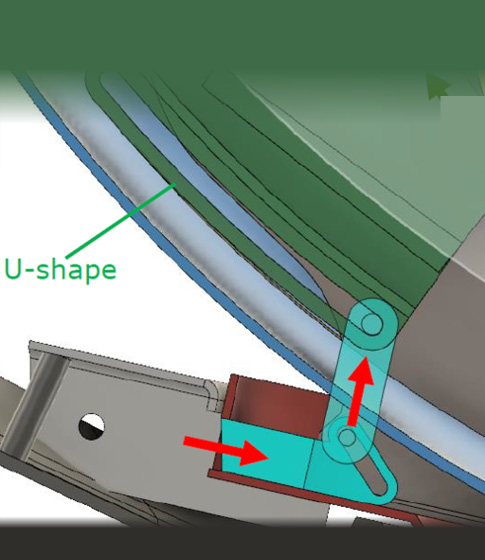

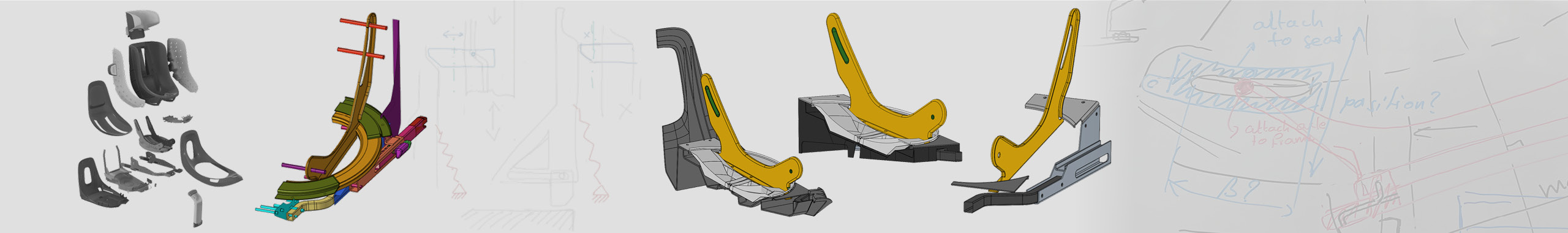

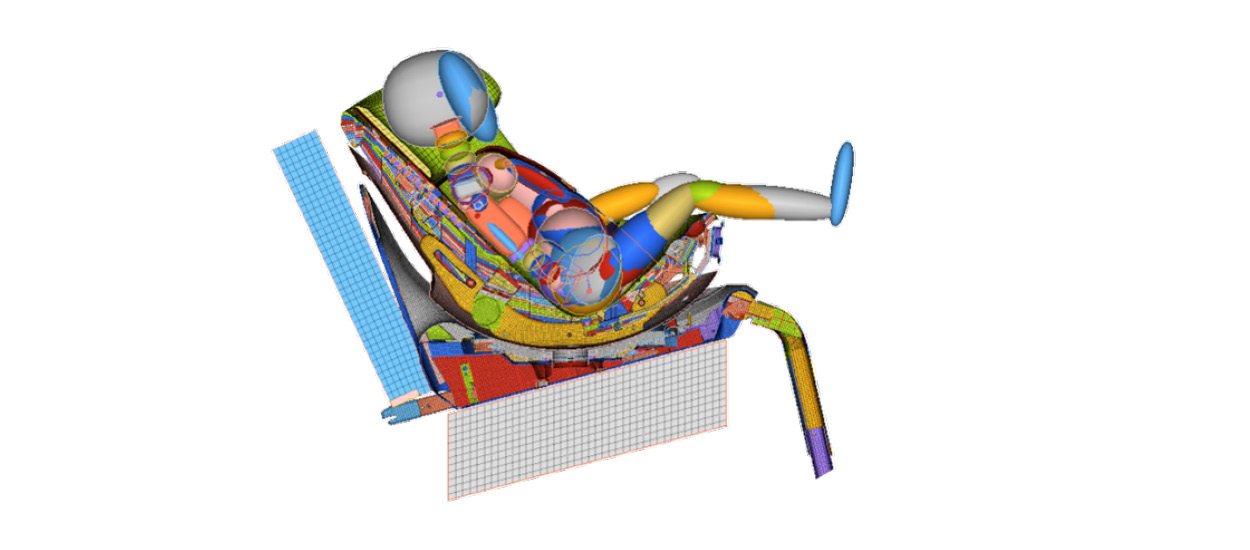

Swandoo challenged us with a short time-to-market development for a new UN-ECER129 rotation toddler seat. Most seats need quite some steel but Swandoo set the goal at a 80-20% plastic-steel ratio for most parts. A perfect challenge to tackle with CAE driven design. The project was finished within one year, where most of these projects take at least two years.

3 stage verifications

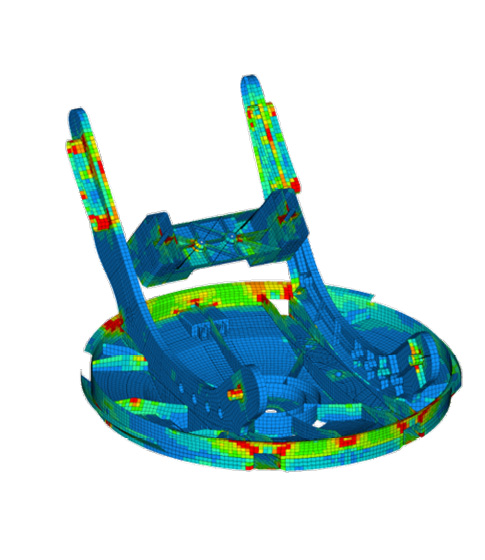

Three validation rounds simulated a CAD status of 45%, 75% and 90%. Every phase pointed out where improvements were needed and came up with possible solutions. Meanwhile constantly keeping the user, manufacturablity and carseat legislation in mind. We focussed on reducing steel in the recline and rotation structure so the weight of the seat was reduced with 10% and saved costs by updating the design.

services in this project

aesthetics & design

structural finite element analysis

usability studies