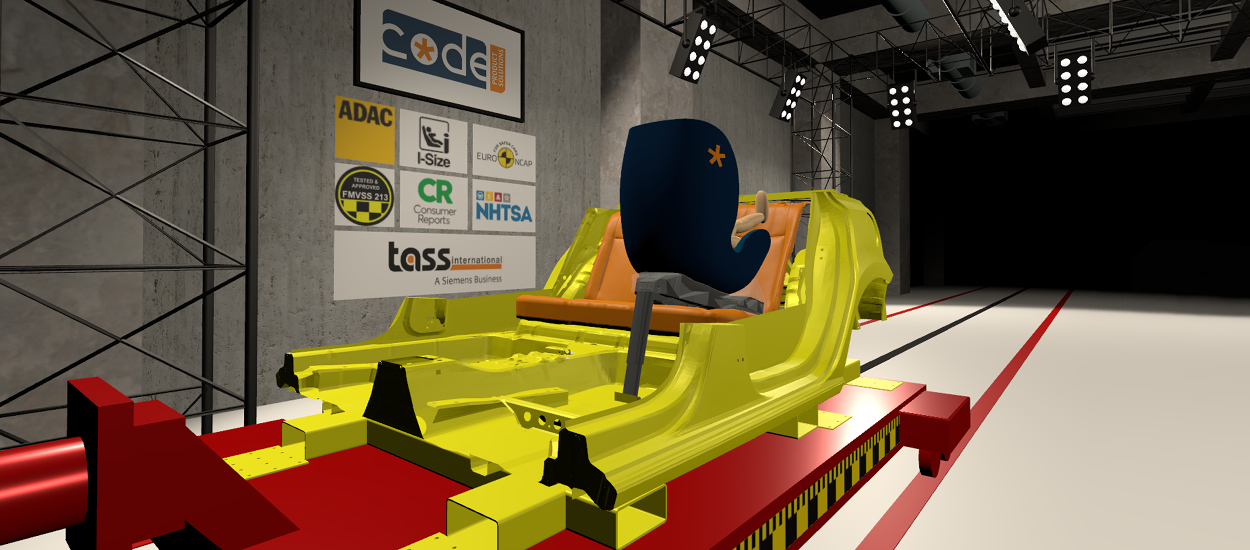

simulation technology

Predict product behaviour before building the first prototype! Less costs, higher performance, lower project risk and time efficiency.

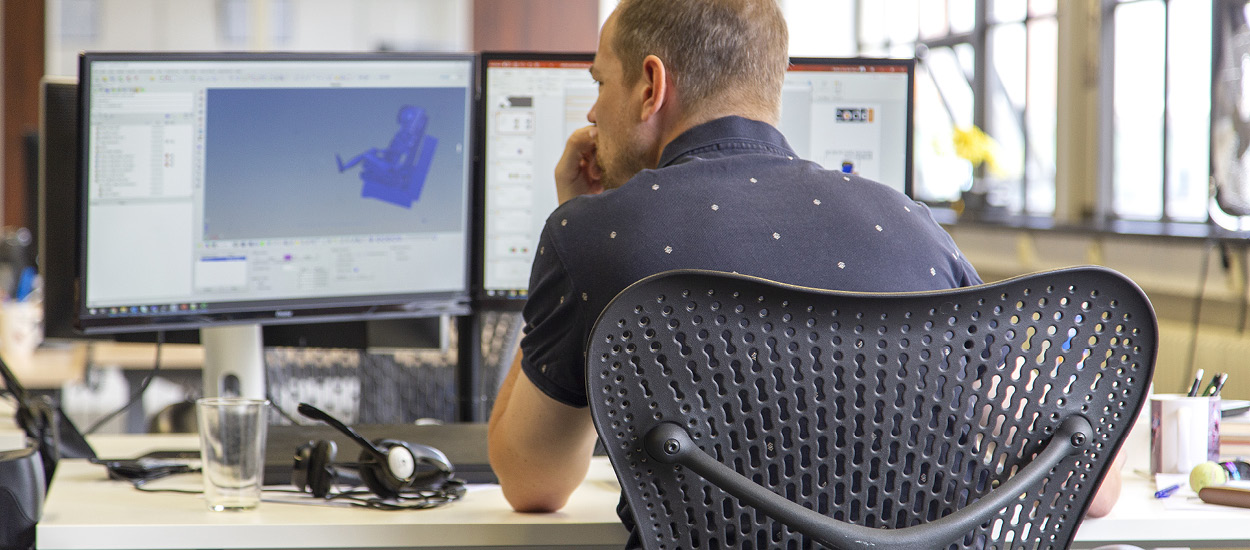

fast design iterations

From mechanical, flow, thermal and multibody to injection moulding analysis: frequently made iterations in product development lead to valuable insights like quicker and better decisions.

efficient trouble shooting

Next to avoiding trouble shooting, simulation technology can also be used for quick root cause analysis and fast solution driven iterations.

services

simulating ahead of reality

"Understand applications to provide direct and honest insights."

Dion Besselink

+31 (0)88 115 1900

info@code-ps.com

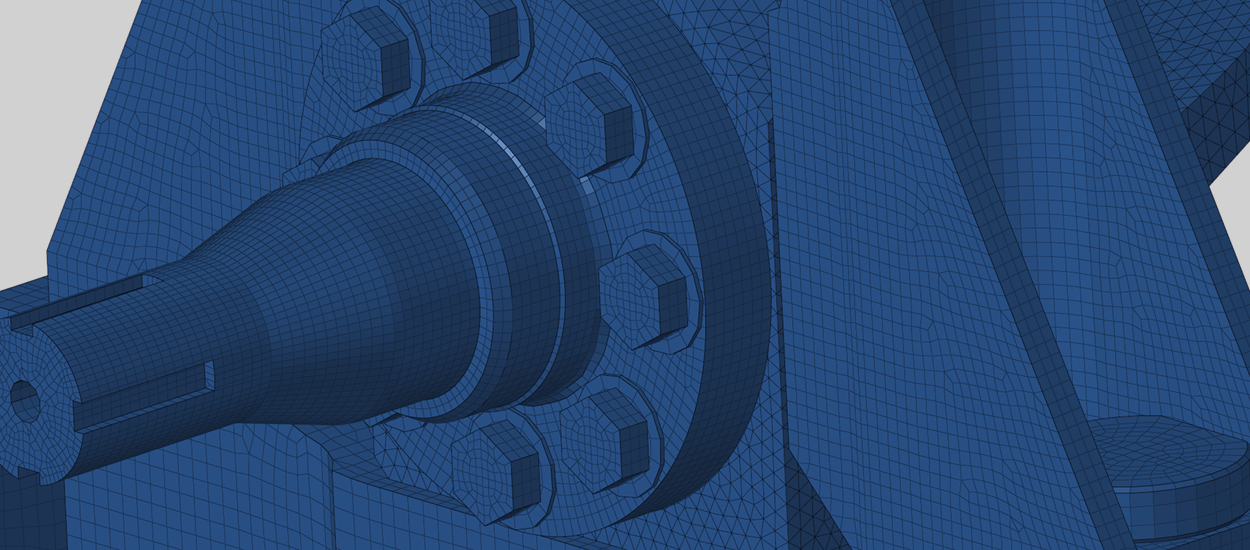

structural finite element analysis

Finite element analysis (FEA) adds big value at the start of a development process with expertise in static and dynamic structural mechanics.

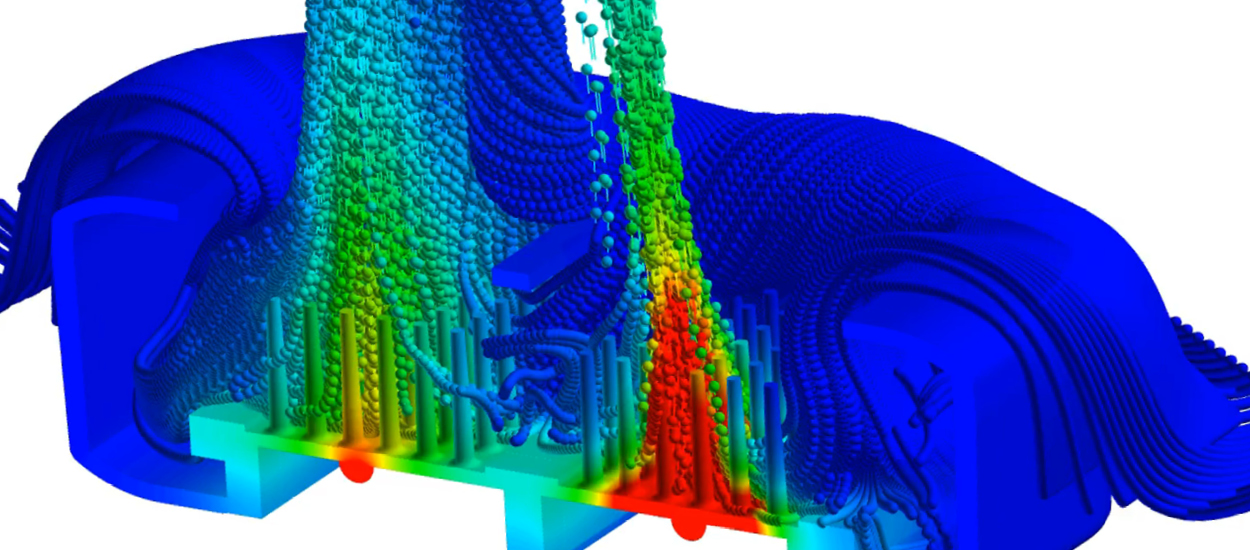

computational fluid dynamics

An important aspect of product development is to understand the flow of fluids, such as liquids or gases. CFD gives detailed insights into the interaction between structures and fluids. An efficient alternative to measurements.

speeding up simulations

Apply Multibody Dynamics (MBD) to study dynamic behaviour of systems. MBD enables early insights in the effect of design parameters on the performance.

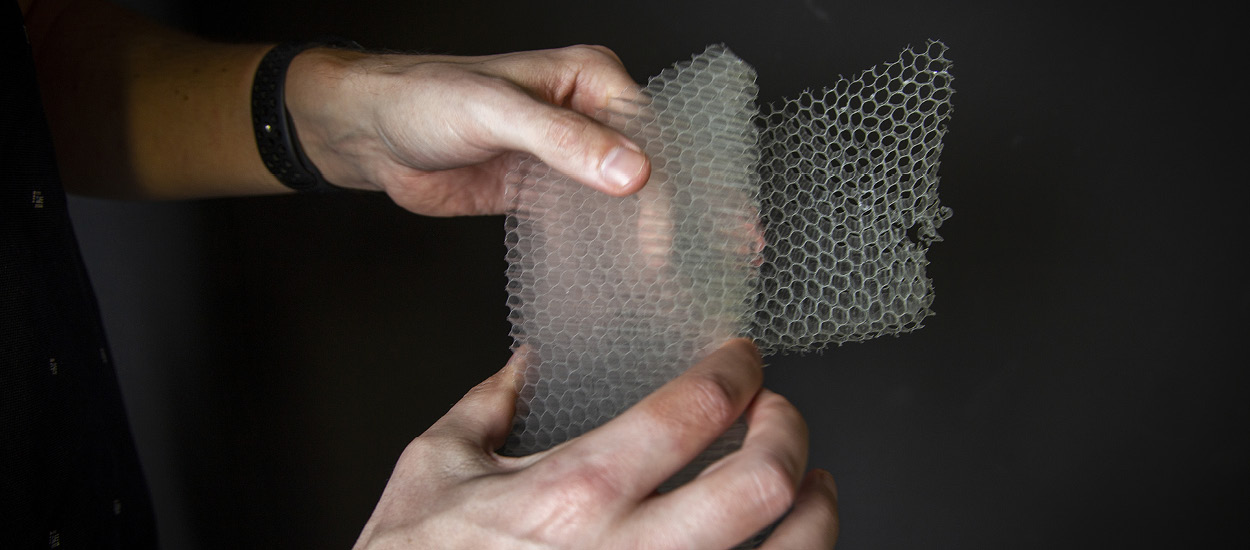

material characterization

Proper data describes the behaviour of materials. This is the key to performing purposeful simulations. We provide the knowledge of behavioural qualities of engineering plastics even when limited information is available.

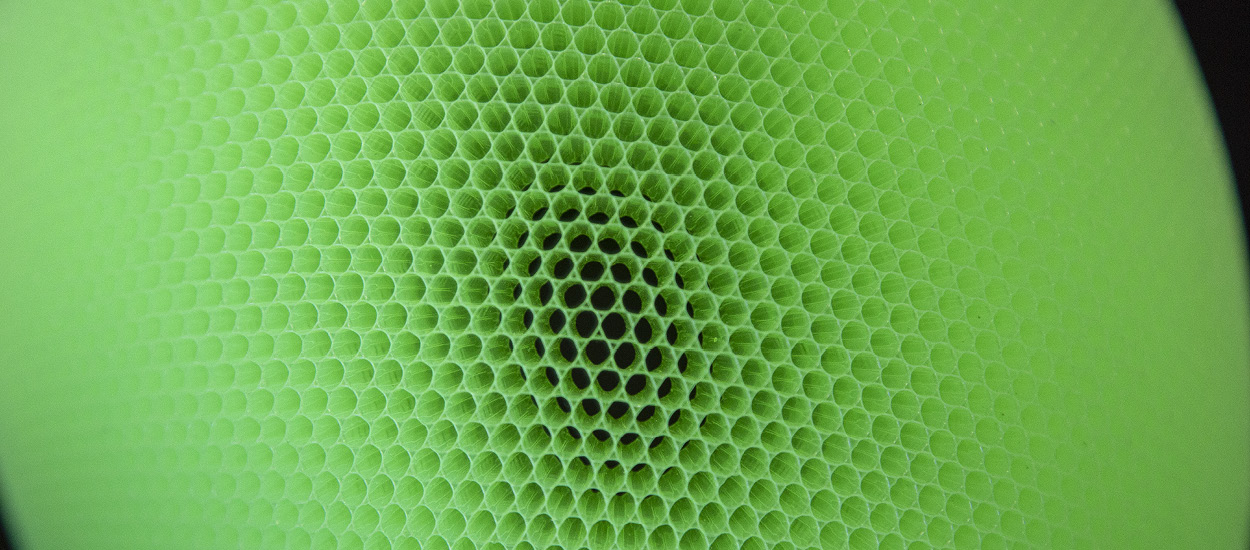

advanced injection moulding simulations

Quality is improved, scrap is reduced and expensive tool revisions are avoided by optimizing tooling and gating. This technique predicts several aspects related to filling, welding lines, air traps, warpage and other important aspects of the injection moulding process.